Due to its exceptional physical and chemical properties, black tungsten wire is widely used in lighting, electronics, photovoltaics, and high-temperature industries. As a processed product of the high-melting-point metal tungsten, tungsten wire possesses unique properties that enable it to perform exceptionally well in extreme environments. The following details its key characteristics.

1. High Melting Point

Black tungsten wire has a melting point of approximately 3422°C, the highest of all pure metals. This property enables it to maintain structural stability at extremely high temperatures, making it suitable for applications such as incandescent lamp filaments and high-temperature furnace heating elements. Even at temperatures approaching 3000°C, it maintains mechanical strength, preventing melting or deformation.

2. High Density and Strength

Tungsten has a density of 19.25 g/cm3, giving black tungsten wire its high mass concentration. After drawing and heat treatment, its tensile strength can reach 1500-4000 MPa, while its hardness (approximately 7.5 on the Mohs scale) is extremely high. It also exhibits excellent wear resistance, making it suitable for high-stress applications such as photovoltaic wafer cutting and TIG welding electrodes.

3. Low Thermal Expansion Coefficient

Black tungsten wire has a thermal expansion coefficient of only 4.5×10??/°C, minimizing thermal expansion. This ensures dimensional stability at high temperatures, making it suitable for precision instruments and high-temperature equipment, such as thermocouples and filament holders, by preventing deformation caused by temperature fluctuations.

4. Excellent Electrical and Thermal Conductivity

Black tungsten wire has a resistivity of approximately 5.5×10?? Ω·m (20°C). While its electrical conductivity is lower than that of copper, it remains stable at high temperatures, making it suitable for use as X-ray tube cathodes or electron emitters. Its thermal conductivity is approximately 173 W/(m·K), effectively dissipating heat and making it suitable for high-power electronic devices. 5. Chemical Stability

At room temperature, black tungsten wire is highly resistant to acids (such as hydrochloric acid and sulfuric acid), alkalis, and moisture, maintaining a stable surface. However, in high-temperature (>400°C) oxidizing environments, tungsten trioxide (WO?) is easily formed, requiring protection in a vacuum or inert atmosphere (such as argon) to prolong its life.

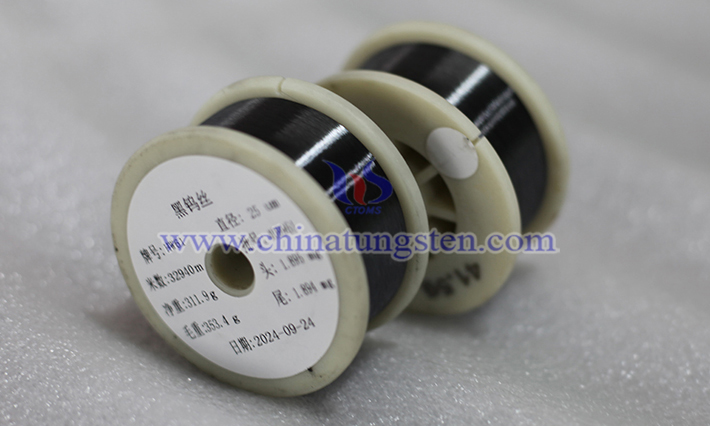

6. Surface and Processing Characteristics

Black tungsten wire has a gray-black metallic luster and is named "black tungsten wire" due to the slight oxidation during processing. Annealing can increase ductility and improve processability, but its high hardness requires precision equipment and high temperatures (1000-1300°C) for drawing and forming, often using diamond molds.

7. Low Emissivity

Black tungsten wire has a low radiative emissivity (approximately 0.1-0.3), resulting in high efficiency in high-temperature radiative heat transfer, making it suitable for use as a filament and heating element, minimizing energy loss.