The main difference between black tungsten wire and cleaned tungsten wire lies in surface treatment and appearance: black tungsten wire has a gray-black color due to the presence of graphite emulsion on its surface; cleaned tungsten wire is black tungsten wire that has been alkaline washed or electrolytically polished, resulting in a silvery-white surface with a smooth finish, making it suitable for high-precision and high-temperature environments. Each type has its own advantages depending on the application requirements.

1. Surface Characteristics

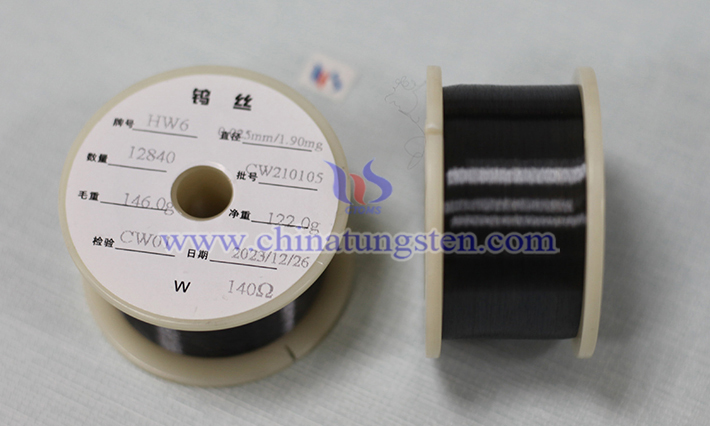

Black tungsten wire has a layer of graphite emulsion on its surface. This is residual lubricant used during the drawing process, resulting in a gray-black color and a slightly rough surface with a metallic luster. The graphite emulsion improves lubricity during processing, but may affect surface finish. Cleaned tungsten wire, on the other hand, is black tungsten wire that has been alkaline washed or electrolytically polished to remove the graphite emulsion and oxides, resulting in a silvery-white surface with a smooth, high-gloss finish, making it suitable for applications requiring high appearance requirements.

2. Processing Technology

Black tungsten wire is made by high-temperature drawing from a tungsten blank. Graphite emulsion is retained on the surface to reduce die wear, allowing direct forming without additional cleaning. Cleaned tungsten wire requires further processing, typically using sodium hydroxide solution alkaline cleaning or electrolytic polishing to remove surface impurities and oxide layers. This process is more complex and slightly more expensive.

3. Chemical Properties

Because of the graphite emulsion covering its surface, black tungsten wire is slightly less chemically stable than cleaned tungsten wire. Especially in high-temperature oxidizing environments, the graphite emulsion may decompose and shorten the tungsten wire's lifespan. Cleaned tungsten wire, due to its clean surface, is more resistant to oxidation and corrosion, making it suitable for long-term use in vacuum or inert gas environments.

4. Physical Properties

Both are made of tungsten and have similar melting points (3422°C), density (19.25 g/cm3), thermal expansion coefficient (4.5×10??/°C), and electrical and thermal conductivity. However, cleaned tungsten wire, due to its smoother surface, may have a slightly lower resistivity and provide more stable performance in electron emission applications (such as X-ray tube cathodes). The rough surface of black tungsten wire may increase contact resistance, affecting certain precision applications.

5. Applications

Due to its low cost, black tungsten wire is often used in applications where surface finish requirements are less stringent, such as incandescent lamp filaments, high-temperature furnace heating elements, and wire saw substrates for photovoltaic wafer cutting. Cleaned tungsten wire, with its smooth and pure surface, is suitable for high-precision electronic devices (such as electron sources in scanning electron microscopes), TIG welding electrodes, and microelectrodes in medical devices.

6. Cost and Efficiency

Black tungsten wire requires no additional cleaning, resulting in high production efficiency and low cost, making it suitable for large-scale industrial applications. While alkaline cleaning or electrolytic polishing of cleaned tungsten wire increases process steps and costs, its excellent surface quality meets the demands of high-end applications.