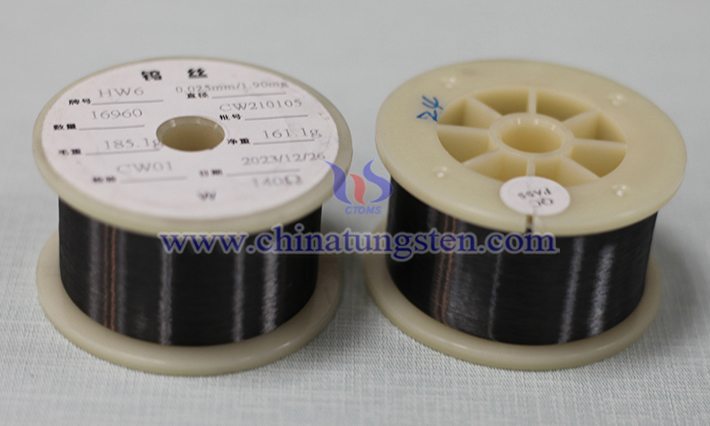

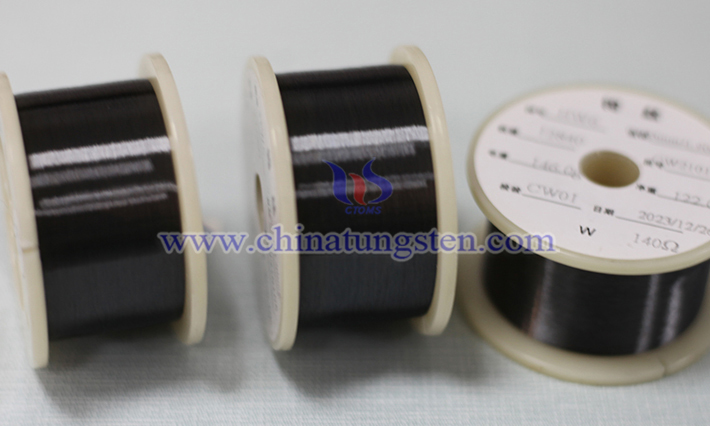

Due to its high melting point, high strength, and corrosion resistance, black tungsten wire has important applications in lighting, electronics, high-temperature industrial applications, medical treatment, welding, photovoltaics, and emerging fields. Although some traditional uses have been impacted by new technologies, its irreplaceable nature in high-temperature, high-precision applications ensures continued demand.

1. Lighting Industry

Due to its high melting point and excellent electron emission properties, black tungsten wire is an ideal filament material for traditional incandescent and halogen lamps. Despite the increasing popularity of LED technology, black tungsten wire remains widely used in high-brightness lighting equipment such as photographic and stage lights due to its high-temperature resistance and stability.

2. Electronics Industry

Black tungsten wire is widely used as hot cathodes or heating elements in electronic devices, including vacuum tubes, cathode ray tubes, and X-ray equipment. Its reliability in high-temperature vacuum environments makes it irreplaceable in devices such as picture tubes. 3. High-Temperature Furnaces and Heat Treatment

Black tungsten wire's high heat resistance and chemical stability make it an ideal material for high-temperature furnace heating elements. In vacuum or inert gas furnaces (such as molybdenum furnaces and ceramic sintering furnaces), black tungsten wire can withstand temperatures exceeding 2000°C and is widely used in materials science, metallurgy, and semiconductor manufacturing. It is also used in thermocouple protection sleeves and high-temperature testing equipment, ensuring long-term stable operation under extreme conditions.

4. Medical Applications

In the medical field, black tungsten wire, due to its high density and corrosion resistance, is often used as electrodes or target components in X-ray and CT equipment. Its high melting point ensures the stability of the equipment in high-energy environments.

5. Scientific Research

In scientific research, black tungsten wire is used as a cathode emitter in scanning electron microscopes (SEMs). Its high electron emission efficiency and long life make it suitable for high-precision imaging. It is also used in precision instruments such as mass spectrometers, meeting the requirements of high temperatures and vacuum conditions. 6. Industrial Cutting and Welding

Black tungsten wire is used as an electrode material in plasma cutting and tungsten inert gas welding (TIG welding). Its high-temperature resistance and arc erosion resistance make it stable under extreme conditions.

7. Photovoltaic Applications

In the photovoltaic industry, black tungsten wire is used in the diamond wire electroplating process during silicon wafer cutting. Black tungsten wire is electroplated with diamond particles to create cutting wire for slicing silicon ingots into thin wafers. Its high strength and wear resistance ensure cutting accuracy and efficiency, making it widely used in solar cell production.